Rail Mounted Container Gantry Crane Features

a). High efficiency, make full use of yard, high automatic

b). Few fault, lower energy consumption, low cost

c). Wide span, can step astride 14 or more containers

d). Can stow 5 to 6 floors containers

e). Make full use of yard, so that it can store more containers

f). Simple structure, easy maintenance, reliable operating

g). Electric drive, save energy

h). Crane travels along the rail, not flexible, working range is limited

i). Applied to stacking area and greater throughput of container port

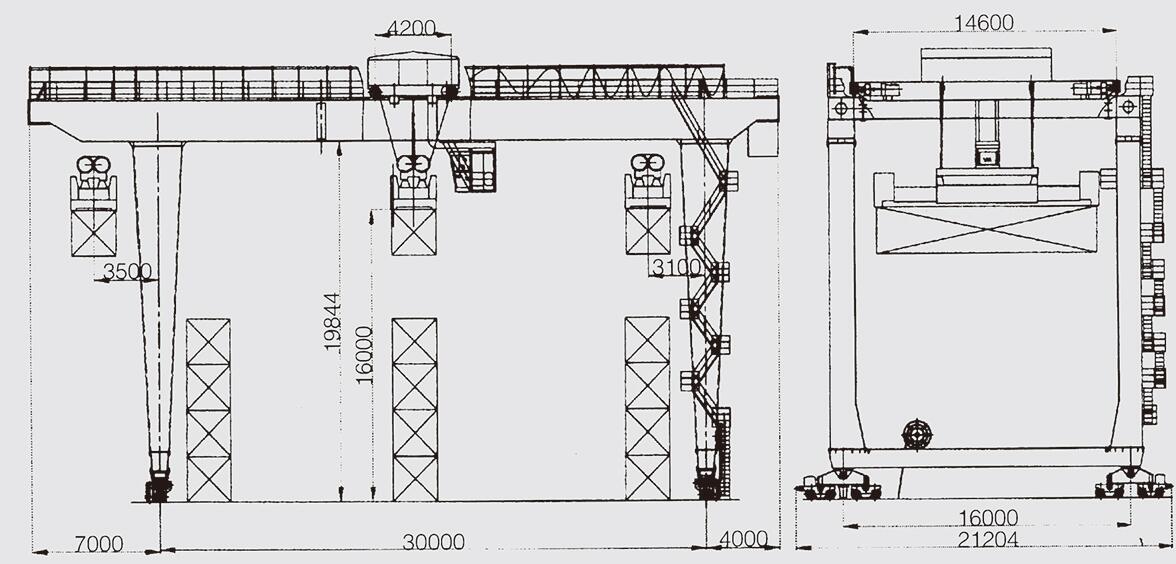

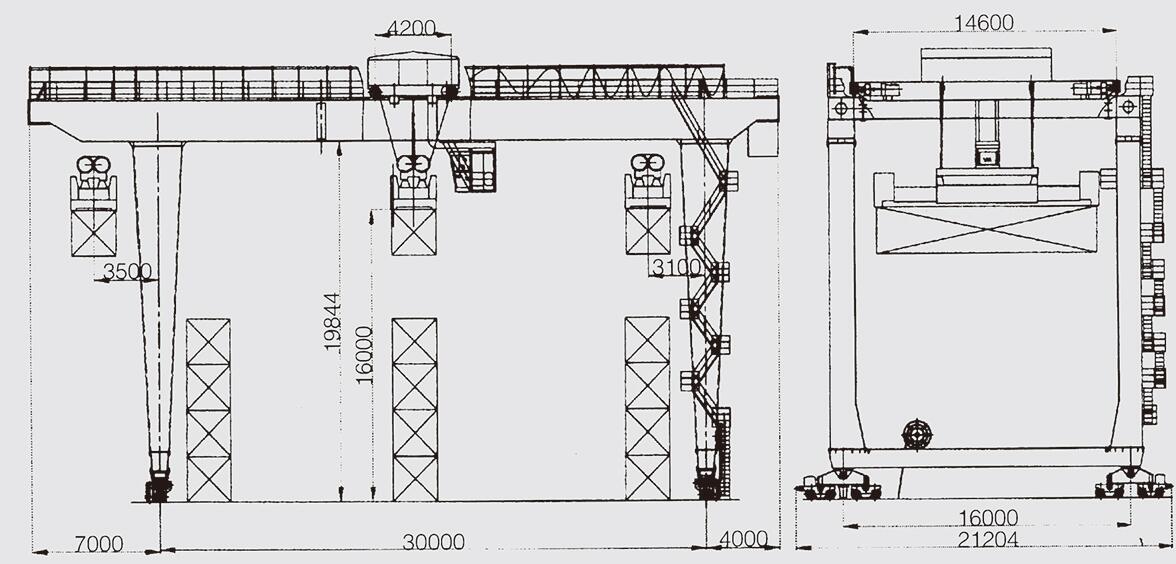

Container Gantry Crane Design

Rail Container Gantry Crane Structures

Rail

container gantry crane consists of main beam, flexible and rigid gantry legs, running trolley, hoisting mechanism, large car running mechanism, electrical system, operating cab, etc.

1. Main girder:

Main girder is welded of steel plates, connected by high strength precision bolt. There are sliding rail for trolley to travel upper the girder which is fixed on outrigger by high-tension precision bolt.

2. Outrigger:

a). Consist of rigid outrigger and flexible outrigger, all connection points are connected by high-tension bolt. The ladder is used by operator to enter into cab or arriving at winch when the span>30m, there need a flexible leg aiming at reducing the lateral thrust the trolley has to the rail when the girder load objects.

3. Traveling mechanism:

Traveling mechanism consist of driving gear box and passive wheel box.

a). The driving gear box supplies power to realize the crane’s traveling.

b). what the difference between driving gear box and passive wheel box is that passive wheel box lacks transmission structure such as dynamo, reducer and a pair of exposed gear.

4. Trolley with hoist:

Trolley frame welded of steel plate is the loading and traveling mechanism of trolley with hoisting. Winch is the lifting mechanism of trolley. When it works, wire rope affects the pulley as rising and falling movement, which makes suspended objects lifting and lowering Warning: wire ropes need to be examined regularly and changed in time if there is a 10% broken wires, loosen wires and wearing down.

5. Cab:

a). Glass window through which one can watch overall working condition is installed in the front and two sides of the cab. Electric cabinet as a group of independent cabinet, fixed outside of cab is connected by control cable and linkage station which is set up in the cab.

6. Electrical system:

a).Lifting motor, crane traveling motor and hydraulic power motor are included. The whole electrical system is controlled by PLC.

b). two ways to operate the crane: cab operating and remote controlling.

c). Electric components are imported from Schneider in Germany.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)